Kumedi, Indore, Madhya Pradesh

- GST NO. : 23AJEPJ7846G1Z7

View Mobile Number

| Business Type | Manufacturer, Exporter |

| Brand | Fenton |

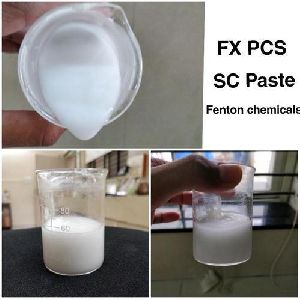

| Color | Milky White |

| PH Value | 6.0 to 7.0 |

| Click to view more | |

Product Details

Packaging Type

HDPE Carboys

Packaging Size

50 Kg

Physical State

Paste

With our spacious experience & knowledge, we are engaged in offering a wide grade of FX D3033 Silicone Based Defoamer. Our offered additives are available in different packaging options to meet the demands of our clients. The provided additives are processed using quality tested chemical compounds and cutting edge technology in adherence with industry norms. Apart from this, these additives are checked on different parameters by quality examiners.

Features:

- Purity

- Stability

- Accurately processed

Other Details:

- Defoamer for Paints, Paper, Textile industries, Sugar industries, Effluent treatment plant

- A defoamer or an anti-foaming agent is a chemical additive that reduces and restrict foam formation in industrial process liquids

- The terms anti-foam agent and defoamer are often mixed up since these are often the same products

- It depends on where it is in used

- A defoamer is normally used to enhance process speed and reduce other problems raised due to foam formation

- It addresses both problems with surface foam and entrained/entrapped air

Properties:

- Generally a defoamer is insoluble in the working system and has surface active properties

- It has affinity to the air-liquid surface where it destabilizes the foam structure

- This is causing rupture of the air bubbles and break down of surface foam

Specifications:

- Diko-Foamfin works on "Dispersion basis" Hence for better result use in diluted form at the grinding stage and part at the finishing stage

- Prepare 30% Diluted solution of Diko-Foamfin in cold water

- Use as Antifoamer: Add diluted Diko-Foamfin solution at grinding stage before addition of extender where foams are likely to be formed

- Use as Defoamer: Spray the diluted solution of Diko-Foamfin whenever foam is noticed

Appearance: Milky white, viscous paste

Ionic Nature: Non-Ionic

Looking for "Silicone Based Defoamer" ?

Kilogram

Explore More Products